Who we are

YTT Cold Chains are multipurpose andare the most advanced cold storage in Northern India. It started in year 1993, At YTT Cold Chains we have 8 individually controlled multi-commodity storage chambers at par with International Standards, suitable for Apples, Oranges, Potatoes (Sugarfee), Carrots, etc.

All goods are kept under extremely hygienic conditions and we give lot of emphasis to overall cleanliness of the cold storage plant. Being a NHB compliant cold storage plant we have 100% power back up ensuring uninterrupted power supply and best technology for refrigeration. Products stored at our plant have minimum shrinkage ensuring best quality of stored products that are as good as straight from the farm products. We are located in Hathras Road, Agra

Our Services

Our Cold Chains are suitable for a diversified range of perishabels. We have made use of the most advanced available technology at par with international infrastructure that includes 100% power backup and usage of PUF Panels. We have used best safety measures , latest Fire protection system meeting the NHB guidelines

Renting Process

We offer chambers on lease. Our chambers are of different capacities 3 Lacs Bags i.e. 15 thousand metric tones that can be availed from short term to long term purposes appropriate for various needs and specifications as per the demand of our clientele.

Refrigeration Process

We have used highly sophisticated machinery and most modern coil, which makes it the most advanced available plant in Northern India. We have made optimum use of technology for making it a new age plant replacing the inefficient old method of cooling systems such as bunker type coils or floor mounted diffusers. An ammonia-glycol plant which leads to reduced ammonia usage and better cooling and safer working conditions.

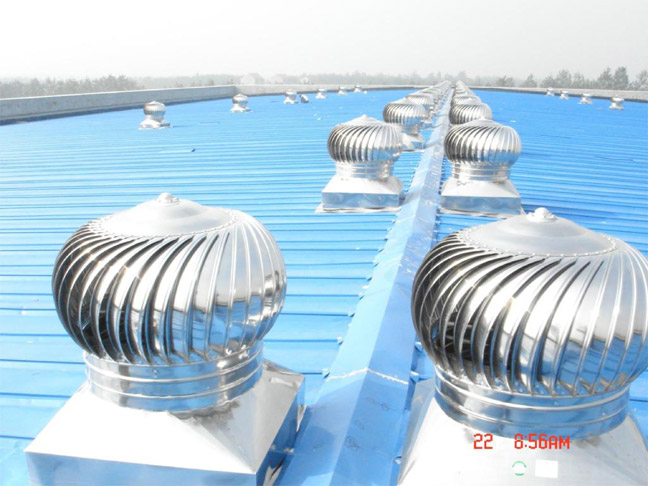

Heat Recovery Ventilators

Temperature, humidity and the Carbon Dioxide levels inside the chamber are maintained at prescribed levels to ensure the freshness and quality over the period of storage which may last up to 10 months. To ensure maintenance of desired Carbon Dioxide levels, we use ventilation i.e. HRVs (heat recovery ventilators). The purpose of ventilation is to introduce fresh oxygen rich outside air into the cold storage and simultaneously exhaust the stale Carbon Dioxide polluted air from the cold storage to the outdoors. A well designed ventilation system maintains an acceptable level of Carbon Dioxide which is essential for maintaining the freshness, taste and quality of the food products. Contact Details : COLD STORAGE–11B/38, NARAICH, HATHRAS ROAD, OPP. SBI, AGRA 9837068235.